There are mainly two types of Disc brakes used nowadays: mechanical disc brakes, which operate with cables, and hydraulic disc brakes, which operate with hydraulic fluid in a fully sealed line.

In this article, we will discuss Hydraulic Disc brakes which are commonly used.

Table of Contents

What Is A Hydraulic Disc Brake?

Hydraulic disc brakes are a type of disc brake in which hydraulic fluid is used instead of wires in a fully sealed line.

Construction Of Hydraulic Disc Brakes

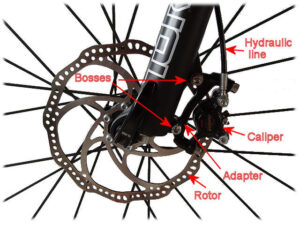

The most common arrangement of hydraulic disc brakes for rider vehicles, motorcycles, scooters, and mopeds, consists of the following:

- Foot pedal or lever

- A pushrod (also known as an associate degree activating rod)

- A brake cylinder assembly containing a piston assembly (made from either one or 2 pistons, a come spring, a series of gaskets/ O-rings, and a fluid reservoir)

- Reinforced hydraulic lines

- Brake caliper assembly sometimes consists of 1 or 2 hollow metal or chrome-plated steel pistons (called caliper pistons), a group of thermally conductive restraint associated degreed a rotor (also known as a brake disc) or drum hooked up to the shaft.

The system is typically full of a glycol-ether primarily based brake fluid (other fluids may additionally be used).

At just once, rider vehicles ordinarily utilized drum brakes on all four wheels. But disc brakes have shown higher chilling and larger resistance to ‘fading’ and area unit thus usually safer than drum brakes.

Working Principle Of Hydraulic Disc Brakes

In a hydraulic disc braking system, when the foot pedal is flattened, a pushrod puts forth the force on the piston(s) within the brake cylinder, causing fluid from the brake fluid reservoir to flow into the pressure chamber through a compensating port. This ends up in a rise within the pressure of the complete mechanism, forcing fluid through the hydraulic lines toward one or a lot of calipers wherever it acts upon one or a lot of caliper pistons sealed by one or a lot of seated O-rings (which forestall outpouring of the fluid).

The brake caliper pistons then apply force to the restraint, pushing them against the spinning rotor, and therefore the friction between the pads and therefore the rotor causes a braking torsion to be generated, retardation the vehicle. The heat generated by this friction is either dissipated through vents and channels inside the rotor or is conducted through the pads, which unit of measurement factory-made from specialized heat-tolerant materials like kevlar or forge glass.

Following the unharness of the brake pedal/lever, it allows the spring(s) within the brake cylinder assembly to take the master piston(s) back to position. This action reduces the hydraulic pressure on the caliper, then applies suction to the brake piston at the caliper assembly, moving it back to its spot and allowing the obstacle to unhitch the rotor.

The hydraulic braking system is intended as a closed system: unless there’s a leak within the system, none of the brake fluid enters or leaves it, nor will the fluid get consumed through use. Outpouring could happen, however, from cracks within the O-rings or a puncture within the brake line. Cracks will kind if 2 forms of brake fluid area unit mixed or if the brake fluid becomes contaminated with water, alcohol, antifreeze, or any range of alternative liquids

Advantages Of Hydraulic Disc Brakes

Below we have listed some of the advantages of Hydraulic Disc Brakes.

- No adjustment is needed. So, no maintenance.

- Better stopping performance

- Fade-free braking altogether conditions. So, no attenuation of brakes.

- Can check wear while not activity the unit

- Easy to replacement of pads compared to Drum brakes.

- More stopping

- Reach adjustment.

Disadvantages Of Hydraulic Disc Brakes

Below we have listed some of the disadvantages of Hydraulic Disc Brakes.

- High braking force required compared to hydraulic brake

- A low lifetime of restraint compared to brake shoes

- Need separate hand-brake mechanism once fitted to rear wheels.

1. Are Water Powered Circle Brakes Worth The Effort?

Water-driven plate brakes have preferable regulation and halting control over mechanical circle brakes, albeit both plate brake styles unfathomably beat edge brakes. Generally speaking, water-driven circle brakes are prevalent as far as execution and proficiency due to the decreased grinding of not having a mechanical link.

2. What is The Advantage Of Water-Powered Circle Brakes?

Advantages of Hydraulic Brakes

Water-driven circle brakes scatter heat completely and disseminate heat more equitably than customary mechanical brakes, and that implies that water-driven brakes are bound to endure longer. This cause is because of brake liquid that opposes intensity and pressure in a water-driven slowing mechanism.

3. Are Water-Driven Circle Slows Down Better Compared To Edge Brakes?

Circle brakes offer preferred regulation over edge brakes, meaning it’s more straightforward for the rider to definitively meter out how much clipping power is created. Top halting power happens not long before the mark of lock-up, and plate-prepared bicycles are better furnished to play with that edge without getting over.

4. Are Pressure-Driven Slows, Down Simple, To Keep Up With?

Water-powered circle brakes expect less support than mechanical ones. Whenever they’re set up, they simply work. The primary explanation is that there is additionally no link that stretches and should be changed. The main normal upkeep you’ll have to do is to supplant the brake cushions as they break down.

Conclusion

So we have discussed the construction, working principle, advantages, and disadvantages of hydraulic disc brakes.

Please share your views about the article in the comment box below.

Cheers!