A hydraulic press is a machine press using a hydraulic cylinder to produce a compressive force.

It uses the hydraulic equivalent of a mechanical lever and was also known as a Bramah press after the inventor, Joseph Bramah, of England. He invented and was issued a patent on this press in 1795.

Table of Contents

What is Hydraulic Press?

The hydraulic press could be a device that is predicated on ‘Pascal’s law’ which states that equal intensity of pressure exerts in all the directions in a confined system.

It’s applied here in a way that if there’s any pressure amendment at one point in a confined system then the same intensity of the pressure can amendment can be seen in other points within the same system.

Construction Of Hydraulic Press

It has two simple cylinders connected, containing an adequate quantity of hydraulic fluid in it. One of the cylinders is larger when compared to the other. Both the cylinders have pistons in them, the larger piston is called a “ram” and a small one a “plunger”.

As seen in the figure, a small force “F” applied on the plunger, in the downward direction, presses the hydraulic fluid below it. This pressure is transmitted equally in all directions and raises the “ram” (Pascal’s Law). The heavier load placed “W” on the “ram” is thus lifted.

Working Principle Of Hydraulic Press

The force applied on the plunger may be small when compared to the weight placed on the ram. Also, the area of the plunger is small in comparison to the area of the ram. But the pressure acting on the plunger (produced by force “F” on the plunger), and the ram are the same (Pascal’s Law). It is the area on which the pressure is acting that makes the difference.

The pressure “P” acts on the ram, which has a large area. The same pressure “P” acting on the plunger has a small area. Also, the distance traveled by the plunger is more when compared to the distance traveled by the ram. This makes a small force applied on the plunger capable of lifting heavy loads placed on the ram.

- Let W = weight to be lifted,

- F = force applied on the plunger,

- A = area of the ram,

- “a” = area of the plunger,

- P = pressure intensity produced by force F.

We know that:

pressure P = Force / Area of plunger

Pressure intensity produced by the force F, P= F/Area of plunger = F/a

As per Pascal’s law, the above intensity P will be equally transmitted in all directions.

Therefore, The pressure intensity on ram = P = F/a = W/A or W= F(A/a)

The above Equation indicates that by applying a small force F on the plunger, a large force W may be developed by the ram.

If the force in the plunger is applied by a lever that has a mechanical advantage (L/l) then the total mechanical advantage of the machine = (L/l)(W/F)

The ratio (L/l) is known as leverage of press. But mechanical advantage can be defined as “the ratio of weight lifted to the force acting on the plunger.”

So M.A = W/F.

Types Of Hydraulic Presses

Below listed are the different types of hydraulic presses available today.

- Universal hydraulic press

- Vertical frame hydraulic press

- Horizontal hydraulic press

- Single column hydraulic press

- Four-column hydraulic press

Uses Of Hydraulic Press

Hydraulic Press may be employed for the following jobs:

- Metal presswork (to press sheet metal to any required shape).

- Drawing and pushing rods.

- Bending and straightening any metal piece.

- Packing press.

Advantages Of Hydraulic Press

Here are some of the advantages of using a hydraulic press.

- Built-in overload protection

- Greater versatility compared to the mechanical press

- It is compact

- It is quiet in operation

- It is safe compared to the mechanical press

- Lower initial and operating cost

- It offers a full-power stroke

- Lower tool cost due to built-in overload protection

Disadvantages Of Hydraulic Press

Here are some of the advantages of using a hydraulic press.

- Handling hydraulic oil can be messy

- There are chances of hydraulic fluid leakage

- Hydraulic lines could burst due to excess pressure

- Some hydraulic fluids can catch fire

- The system gets heated because the hydraulic fluid is forced through the pumps

- It has a low operational speed

- They have relatively high energy consumption

Leverage For A Hydraulic Press

A lever is employed to achieve a ratio once lifting significant weights that hydraulic systems have already got reduced the force which has got to be applied by multiples. By employing a lever together with a press, the ratio gained is additional optimized.

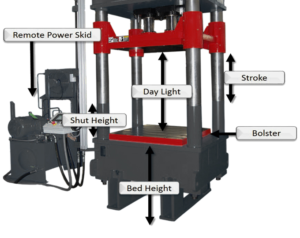

Industrial Hydraulic Press

The picture at the right represents a typical industrial mechanical press. it’s a hard and fast cylinder during which a ram is slippery. To the lower finish of the ram, a movable plate is connected, because the ram moves up and down, the movable plate connected to the ram conjointly moves up and down between 2 fastened plates.

Once a hydraulic fluid is provided beneath air mass into the cylinder, the ram moves down exerting a force, that is adequate to the merchandise of the intensity of the pressure of the hydraulic fluid and therefore the space of the ram on that it acts.

Therefore any material placed between the movable plate and therefore the lower fastened plate gets ironed or maybe crushed betting on the pressure of the oil provided. The come weights, that are suspended at the side of the movable plate, make sure that the ram moves and keep a copy once the pressure within the cylinder is free.

1. What Is The Water-Driven Press Utilized For?

A pressure-driven press is a gadget used to press out materials, support offices in manufacture, get together, and upkeep. It utilizes pressure produced by a siphon to drive a steel chamber into a material at a set power.

2. What Is A pressure-driven Press In Liquid Mechanics?

A water-driven press chips away at the rule of Pascal’s regulation, which expresses that when tension is applied to a restricted liquid, the strain change happens all through the whole liquid. Inside the water-powered press, there is a cylinder that functions as a siphon, that gives a humble mechanical power to a little region of the example.

3. For What Reason Is It Called A Hydraulic Water Press?

Every chamber contains water-powered liquid and one chamber is bigger than the other. The bigger chamber is known as the Ram and the more modest one is known as the Plunger. Fluids don’t pack effectively, which is the reason they are utilized in a water-powered press.

4. What Are The Benefits Of The Water-Powered Press?

6 Advantages of Using a Hydraulic PressCost-Cutting. They enjoy a huge expense upper hand over mechanical presses; assuming that they experience breakdowns, new parts are cheap and the work is straightforward. …

Implicit Overload Protection. …

Calm. …

More Compact. …

Better Control Flexibility. …

More noteworthy is Versatility.

Conclusion

We have discussed the construction of the hydraulic press, its construction, types, advantages, and disadvantages in the above article.

We would like you to share your views in the comment box below.

Cheers!