Every single part of the world is thinking “green” before doing anything and everything because making the mother earth green is the demand of the hour. This is possible only if proper care of natural resources is taken by humans. Saving electricity and hence saving the resources from which it is created is the first step towards saving the earth and the natural resources. Hydraulic ram pump does this important work mainly because it does not require any power source and hence does not contain any parts which move in it.

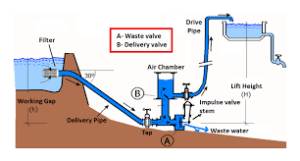

A hydraulic ram is a pump that runs in cycles and uses the power of water (hydropower) to operate. It works similarly to a hydraulic transformer. It is equipment that is used to get a small amount of water without the help of any external energy to a higher level from a large amount of water available at the lower level, which in most cases, is groundwater.

The essential condition for the working of a hydraulic ram pump is that the water present at a small positive head or height should be in a sufficiently large quantity so that it can be carried by the ram pump.

Table of Contents

Working Principle Of Hydraulic Ram:

The principle on which the hydraulic ram pump works is known as ‘Water Hammer’. Water hammer is a surge of pressure or wave that is caused when a fluid (in most cases a liquid but in some cases also a gas), which is moving, is made to stop or change its direction suddenly ( basically the change in momentum).

Water hammer a is a very common phenomenon observed taking place during the flow of any fluid. We can easily say that the water hammer is present just by the noise it makes. Noise is just an indication of the water hammer and not the final effect of it.

Working Of Hydraulic Ram:

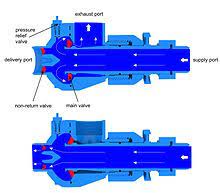

As mentioned earlier, a hydraulic ram operates on the principle of a water hammer, that is, when flowing water is suddenly made to rest, the change in momentum of water (mass) raises the pressure. This rise in pressure is utilized to raise a small amount of water to some higher level. In the beginning, the valve of the water is open and the valve which does the delivery work is closed. The water which comes from the supply tank begins to flow under the force of gravity of the earth and picks up pace and speed giving birth to kinetic energy. This happens until it forces the exhaust valve to close.

The momentum which is mass times speed, of the water flow in the pipe supplying it against now closes the waste or the exhaust valve that in turn causes a water hammer that raises the pressure of water in the chamber. This high pressure of the water makes the delivery valve open and the water enters into the vessel containing air which further compresses the sir which is already present in the vessel. This makes the pressure in the air-vessel high and this pressure closes the delivery valve.

Now the water from the air vessel is forced to flow through the delivery pipe. Under this condition, both the waste or exhaust valve and the delivery pipe remain closed. Gradually, the pressure in the valve chamber becomes low and the exhaust or waste valve again opens and allows the water to pass through it. Then, the flow of water through the supply pipes starts again giving rise to the water hammer in the valve chamber. This cycle gets repeated again and again.

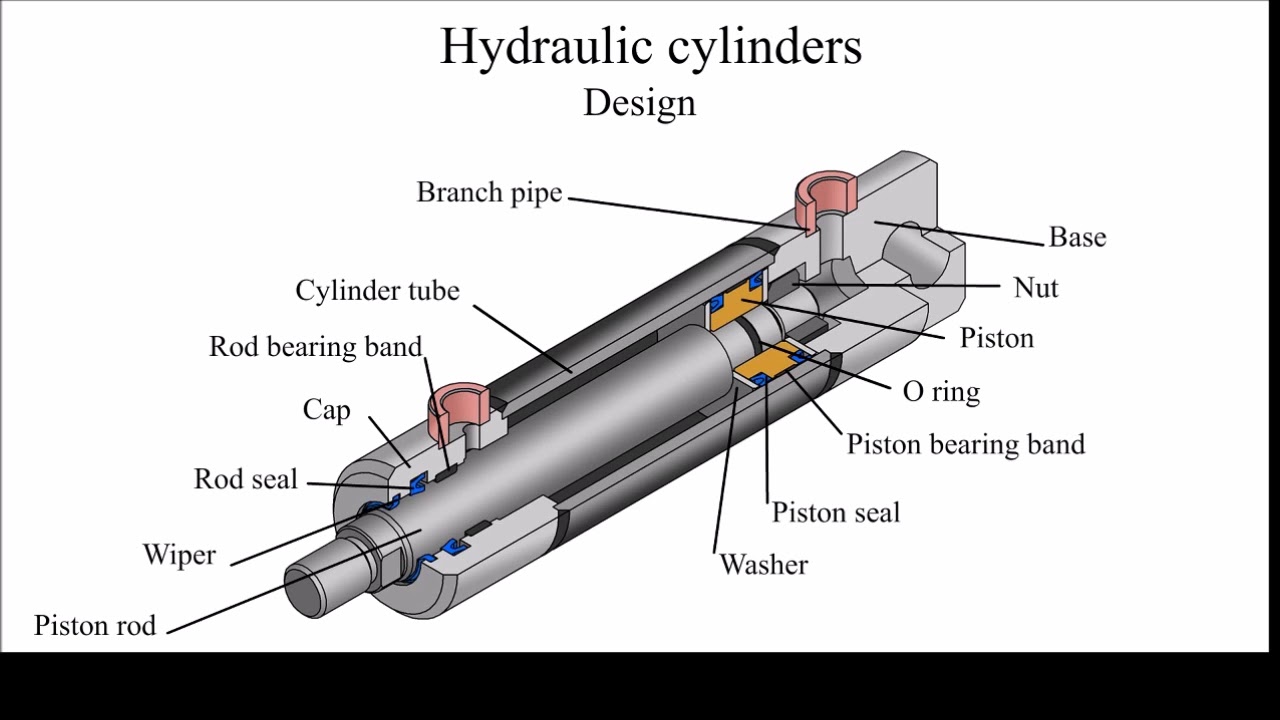

Important Parts Of The Hydraulic Ram:

The main parts of the hydraulic ram pump are:

- Supply tank

- Supply pump

- Valve chamber

- Waste valve or Exhaust valve

- Delivery valve

- Air vessel

- Delivery pipe

- Delivery tank

Advantages Of The Hydraulic Ram:

- Hydraulic ram does not require any prime mover mainly because it is operated by itself.

- The design of a hydraulic ram pump is really simple.

- The cost of maintenance and repairing is very low.

- Its running expenses are also negligible.

- No electricity is consumed because it works only on hydropower.

- It works continuously, which means it will give a regular output.

- Hydraulic ram pumps have a long lifetime.

- Hydraulic ram pumps are reliable as well.

Disadvantages Of The Hydraulic Ram:

- A large amount of water gets wasted through the exhaust valve or waste valve.

- The working of a hydraulic ram pump is very noisy.

- These kinds of pumps are suitable only for certain sites.

- The installation investment could be very high.

Applications Of The Hydraulic Ram:

- Hydraulic ram pumps are used to lift the drinking water from springs to a higher ground settlement.

- It can be installed at any place which has a water flow.

- Hydraulic ram pumps prove very beneficial in the hilly areas where the amount of water flowing at a low level is needed to be raised to higher levels for domestic purposes and even for irrigation.

1. Will a ram pump work in a river?

2. What is a hydraulic ram simple?

3. What is the principle of hydraulic ram?

4. What is a hydraulic ram used for?

Conclusion:

The hydraulic ram pump is a broad prospect that utilizes the abundant surface water of our country. The initial costs of installation of hydraulic ram are high but its maintenance, as well as working, requires very less, almost negligible money.

I hope to work, advantages, as well as disadvantages of hydraulic ram pumps, are clear after reading this article.