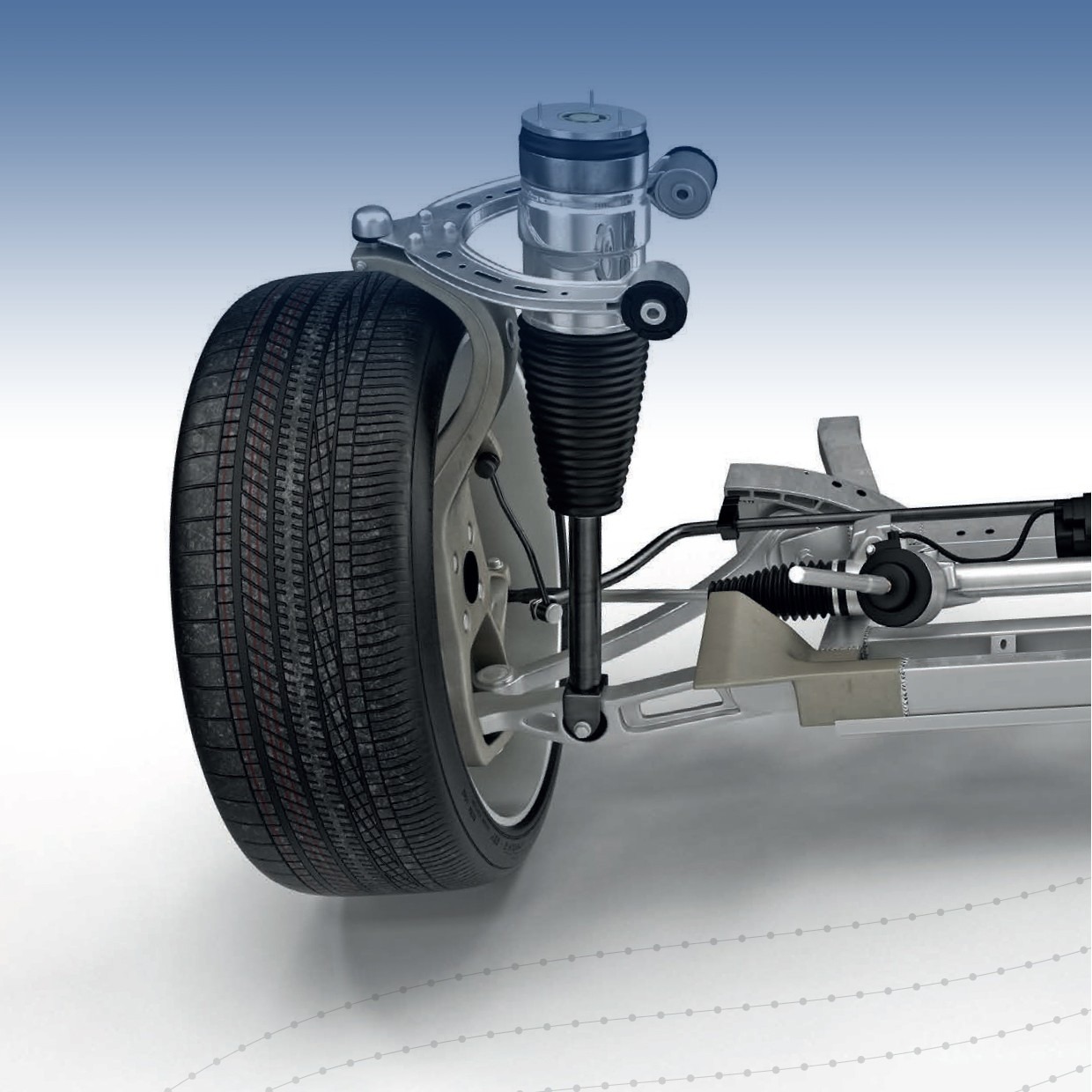

The suspension system is the shock absorbent system a vehicle has. It is a combination of springs, shock absorbers, and linkages, which connects a vehicle to its wheels and enables relative motion between the two. In this article, we dig deep into the topic of Hydraulic vs air suspension.

The suspension system contributes to the car’s handling and braking. The suspension system also protects the vehicle itself and any cargo or luggage from damage and wear.

Here we are going to discuss two types of suspension systems

- Hydraulic suspension.

- Air suspension.

Table of Contents

Hydraulic Suspension

In a hydraulic suspension system, there is something called hydraulic fluid which creates pressure in the “sealed” system. This pressure creates the power which is then transmitted to various other components.

In a hydraulic suspension system, this transmitted power is what causes the chassis to rise off the axle. The Hydraulic system uses fluid and compressed gas in the place of springs to absorb forces emanating from the road surface.

Working Principle Hydraulic Suspension

In a hydraulic suspension system, the action of the wheel pumps oil from one chamber to another via a “damper valve.” Each chamber in the system has a “diaphragm” with compressed gas against which the force generated by the pumped fluid collides and rebounds. The rebound forces the oil back into the original chamber forcing the wheel to grip the road.

Advantages Of Hydraulic Suspension

- The hydraulic suspension system creates a better driving experience compared to the leaf spring suspension system.

- The hydraulic suspension system is that it is customizable. For instance, you can raise the shocks in your vehicle to totally different heights.

- The reaction time of the hydraulic system is better than a leaf spring suspension system

Disadvantages Of Hydraulic Suspension

- The hydraulic suspension system is costly compared to a steel spring suspension.

- Fluid leakage is a common problem of the hydraulic suspension system, which could lead to vehicle damage and expensive repairs.

Air Suspension

Air suspension is a type of vehicle suspension where airbags are used in place of springs. There is an electric or engine-driven compressor, which pumps the atmospheric air into flexible bags, usually made from textile-reinforced rubber.

Unlike a hydropneumatic suspension, which offers many similar features, air suspension does not use pressurized liquid, but pressurized air. The air pressure inflates the bags and raises the chassis from the axle.

Working Principle Of Air Suspension

In the air suspension system, airbags take the place of coil springs and the airbag Is inflated to the appropriate ride height. The system uses an electronic pump to feed air into the airbags through the pressure line. The pump pulls outside air and compresses it, and then sends it to the air tank.

Different lines are used in the system to keep the required pressure in the airbags. Solenoids are used for inflating and vending the airbags by the electronically controlled system. When the system makes arrangements in different driving conditions, the solenoids open and close to keep the required amount of air in the airbags. The electronic system has an electronic control module that controls the analog on/off controls, adjusts ride height, and monitors the pressure in the airbags.

Advantages Of Air Suspension

- Reduced noise, vibration, and harshness, which means better wear on other components in the truck.

- Better fuel consumption.

- Its height adjustability can help with different types of loads. It also comes with a ‘kneel’ mode to help with loading, and a ‘raise’ mode to help clear bumps and rough terrain.

- Improved tire life.

- Less load shifting and damage.

Disadvantages Of Air Suspension

- The Durability of air suspension is less than leaf spring suspension.

- More costly than other suspension systems.

- The weight of the air suspension is greater than leaf suspension and therefore fuel economy benefits aren’t always experienced.

Hydraulic Suspension System Vs Air Suspension System

Let us discuss Hydraulic vs air suspension in detail.

i. Functionality

- Air suspension systems use a bag enclosed in a heavy rubber case with a series of lines connected to a compressor to control the amount of air pumped into each bag, which adjusts the ride quality and height of the vehicle.

- Hydraulic suspensions have a similar mechanism but instead of compressed air, they use hydraulic fluid and a series of coils that are compressed or expanded to create pressure and adjust quality and height.

ii. Ride

- Air suspension systems are known for their smooth ride. This is the primary benefit to the other system, as well as the fact that the quality of ride wins over hydraulics hands down every time.

- Hydraulic suspensions are a little bumpy because the fluid doesn’t compress the same way air does. They can be made smooth with additional parts and upgraded pieces, but it takes more effort and cost.

iii. Response

- Air suspension systems have a slightly longer response time when you’re talking about raising, lowering, or “hopping” a vehicle.

- Hydraulic suspensions raise and lower much quicker than air suspension because the hydraulic fluid doesn’t take as long to compress.

iv. Maintenance

- Air suspension systems require similar maintenance to hydraulics. They can leak, but they are typically easier to repair and a lot less messy, assuming you can find the leaks. Sometimes air leaks are harder to find than fluid leaks.

- The hydraulic suspension is more vulnerable to leaks and they can be a mess. They also require the replacement of seals, pumps, batteries, and fluid on an occasional basis.

v. Cost

- Air suspension systems are significantly less expensive than hydraulics because you can start with a simple setup and enjoy the basic functions at a low cost. You can upgrade specific parts in steps, making it a more affordable system overall.

- Hydraulics suspensions are more expensive initially when compared to the airbag system options in comparable vehicles.

1. Is Hydraulic Suspension Superior To Air Suspension?

For example, an air suspension system provides a smoother ride and better handling than hydraulics. Furthermore, the system can be changed to provide a soft or hard ride depending on the situation. Air suspensions are also well-known for their ease of adjustment. Air suspensions can also help in towing and hauling.

2. Is Hydraulic and Air Suspension The Same Thing?

To absorb road stresses and shocks, the hydraulic system uses oil and pressurized gas instead of springs. While air suspension is a type of car suspension that is powered by an electric or engine-driven air pump or compressor.

3. A 1.5-Tonne Jack Can Raise How Much Weight?

Also, as someone previously stated, 1.5 tonnes is sufficient for a hydraulic suspension superior to air suspension?

For example, an air suspension system provides a smoother ride and better handling than hydraulics.

Conclusion

Air suspension and hydraulics help vehicles to deliver great performance, handling, and capabilities, Hydraulic vs Air Suspension, which is better?

The answer depends entirely on your needs and the performance you want to experience. If you’re looking for something more customizable, consider installing a hydraulic suspension kit. If you’re looking to enhance towing performance and make your drives smoother and more enjoyable, install an air suspension kit.