Cars are very essential in our daily lives, but they can sometimes cause problems, and you may need to be more familiar with why that is happening. You may experience things like your car won’t rev past 4000 rpm in park, gas usage may increase, engine load may increase, or internal issues may limit acceleration. If the engine does not reach the maximum required RPM, it indicates insufficient power and is usually accompanied by other symptoms, significantly reduced power.

Read on to find out why your vehicle’s RPM is stuck at 4000 and how to fix it.

When a car engine starts, the pistons inside the engine move up and down, turning the crankshaft. The crankshaft rotates at a certain number of revolutions per minute (RMP).

Table of Contents

Why Your Car Won’t Rev Past 4000 RPM In Park?

We’ll go over each of these possibilities in depth, as well as how to determine which one is the true culprit.

1. A Restriction In The Exhaust System

If the exhaust gases do not flow sufficiently free from the engine to the tailpipe exit, the engine will not be able to turn. Carbon and sludge buildup on parts can occur in vehicles that have not been driven long enough or as the exhaust system ages.

There are some places where the exhaust system can have limitations:

- The silencer: It is a chamber designed to reduce engine noise that can eventually clog.

- The catalyst converter: The chamber is usually located under the vehicle near the engine end and helps control exhaust emissions, but can clog.

- Dents from driving over rough terrain can damage exposed areas.

As mentioned earlier, it is not just carbon accumulation that leads to emission limits. The exposed part of the exhaust can be physically damaged and the site collapse, resulting in a sufficiently severe flow restriction. Your exhaust systems could be frozen if you live in a cold region.

Turn the car around, and you should feel a nice flow coming from behind the tailpipe. If you think you have a limitation, check it just before you damage your engine.

2. ECM Is Faulty

If you’re having issues with jerking, mis-ignition, poor starting, loss of power, or engine revs, your ECM could be the cause of the problem. There are many symptoms that can be caused by a faulty ECM. To diagnose this problem, you will need an auto electrician or auto repair shop to connect a diagnostic tool to check the error code.

If not the ECM itself, it can provide clues as to what is causing the motor not to run. So it might not be a direct fault of the ECM, but something that is causing the ECM to react in some way. It can register erratic readings from a sensor, which could cause it to trigger lame mode.

The limp mode avoids potential damage by reducing engine power to allow only a limited speed or performance. Other vehicle functions may be limited, such as air conditioning. So it might be worth checking it out and starting there.

3. Clogged Fuel Injectors Need Repair Or Replacement

Clogged or faulty fuel injectors can impair your vehicle’s ability to start, reduce fuel economy, cause erratic behavior related to engine speed, or cause idling issues such as rough idling or very low idling speed.

You may see an engine warning light appear on your dashboard. A repair shop can clean or service the injectors, but if replacement is the only option, it can be expensive. If desired, you can purchase a cleaning kit to clean the injectors yourself.

4. Improperly Adjusted Engine Ignition Timing

- If the ignition timing is not set correctly, you may experience an incorrect idle speed and various performance issues.

- If the timing is too early, your engine will make a small knock when you accelerate or go uphill.

- If the ignition timing is too late, you will lose power. In some cases, you may not be able to spin the motor. You can have a mechanic check the time; this will be a small, inexpensive job. However, if you buy a timing light, you will be able to track your ignition timing for life.

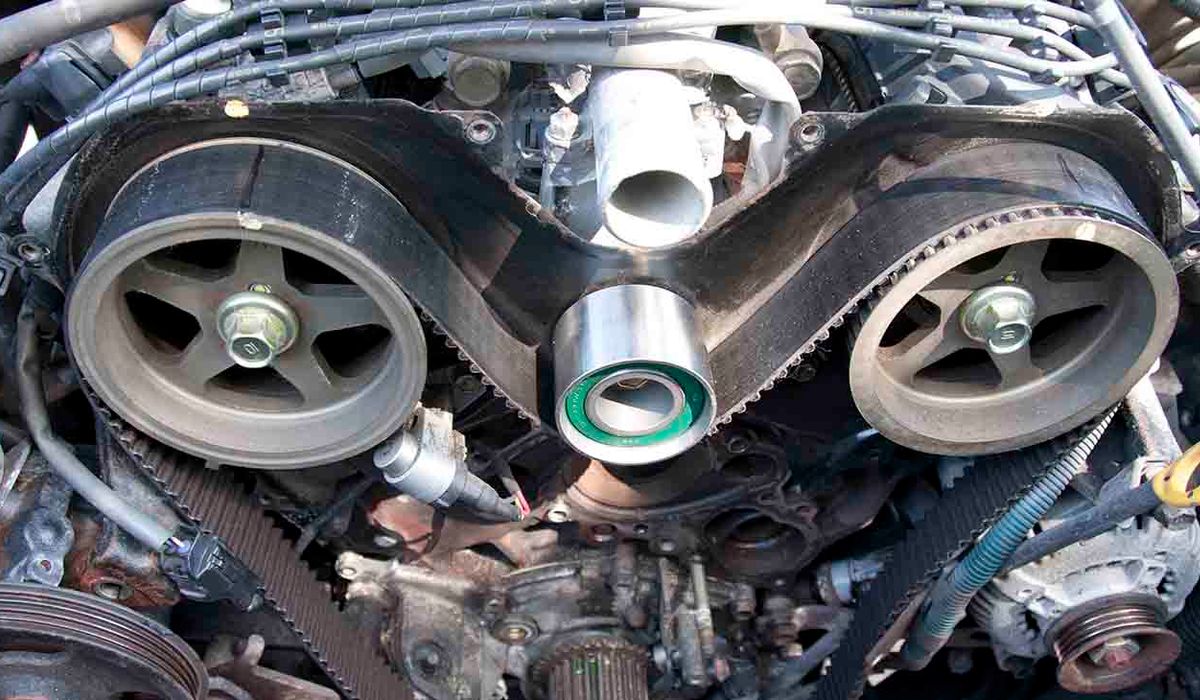

5. Inappropriate Valve Or Camshaft Timing`

In addition to rotation problems or poor performance, improper valve timing can result in a bent valve. This can happen after changing the timing belt or chain. If the engine is still running poorly after the timing correction, you may have a bent valve.

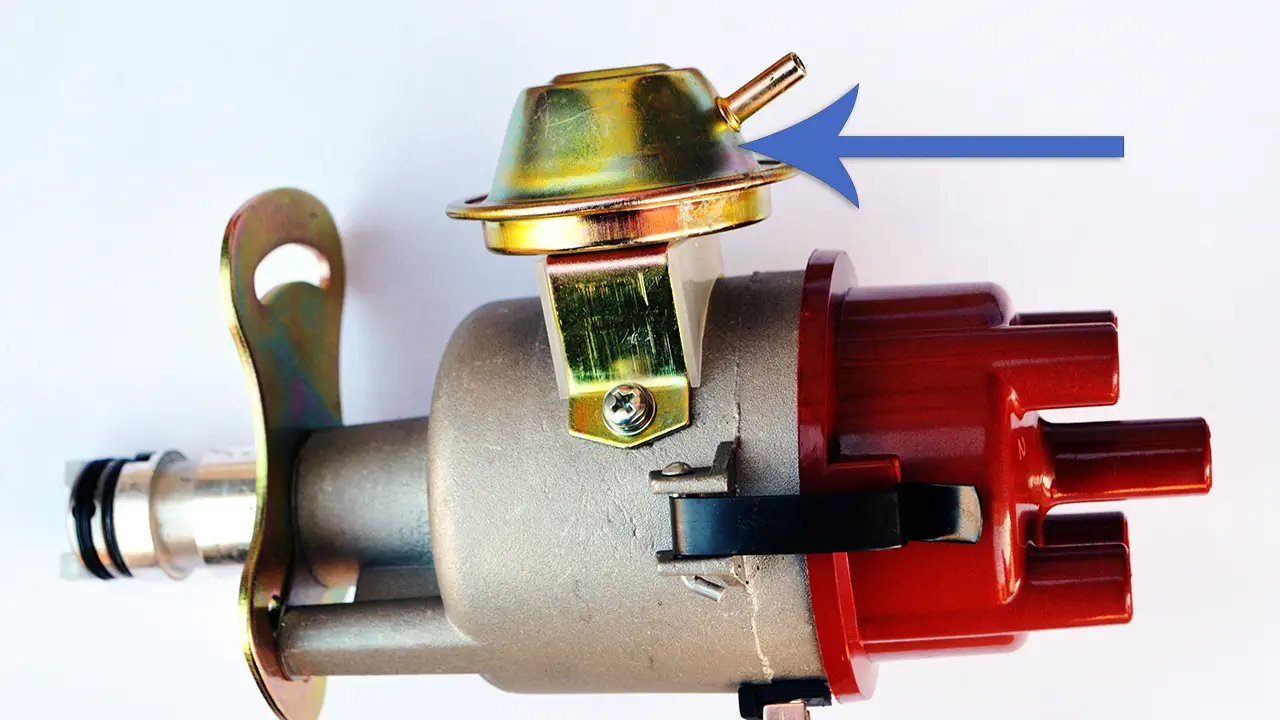

6. Timing Advance Unit Malfunction

Whether your car has a mechanical or vacuum advance unit, a breakdown in either can create major performance difficulties that prevent your engine from revving over 4000 RPM.

The ignition timing is advanced by the advanced unit depending on the amount of stress and RPM your engine is encountering. The engine will lose power and won’t continue to rev as it should if it can’t give sufficient advancement for the ignition timing.

Common advanced unit flaws include:

On vacuum advance systems, a fractured or split diaphragm

- Counterweight springs that are broken or worn

- Both types can benefit from a sticking mechanism.

A repair on these machines is typically not expensive and may even be performed by a beginner, provided a suitable replacement is obtained.

7. Worn-out Valve Springs

When valve springs deteriorate, they are unable to maintain the required tension to guarantee a valve closes consistently when it should. Therefore, something like valve bounce may happen, resulting in incorrect valve positions at the wrong moment, which would limit the engine’s ability to rev. It could very well reach a certain RPM and stop reliably revving beyond that.

Valve spring replacement isn’t very difficult or expensive, so if you have some mechanical expertise and feel comfortable attempting to resolve the issue yourself, it is most definitely doable with adequate advance preparation. This requires much less labor because the cylinder head does not need to be removed.

While you’re at it, it would be a good idea to replace the valve seals. This will lessen the likelihood of the smoke cloud that appears when you start your car for the day. An overhead valve spring compressor is a useful tool for more smoothly compressing the valve spring and removing the retainers.

Once the valve springs have been removed, take care not to let the valve drop. You don’t want it to fall inside the cylinder since then you’d have to take the head off to get it out.

The piston is typically brought down the stroke by spinning the engine, then the cylinder is filled with rope (via the spark plug hole), and the piston is brought back up to the top of the stroke before working on the valves that belong to that particular cylinder. After finishing the previous cylinder and disconnecting the rope, you must proceed with the subsequent cylinders.

8. Malfunctioning Variable Valve Timing

Depending on the load and RPM, variable valve timing aids an engine in achieving peak valve timing. You might not have enough potential for revving if this isn’t working properly. Of course, precise circumstances must exist for this to happen. The repercussions of poor valve timing are well known to mechanics, and a malfunctioning variable valve timing system can have a similar impact. Depending on the type of variable valve timing system that has to be diagnosed and repaired, this type of issue is best handled by a service technician.

9. Failure Of The Ignition Coil

There are several different signs that might indicate an ignition coil failure. One of these is that the engine has a limit on how high it can rev. When the coil is unable to generate a high tension voltage sufficient to appropriately power the spark plug, this occurs. More fuel will go unburned and less power will be generated during the power stroke if the spark is weaker. For the majority of automobiles, replacement shouldn’t be prohibitively expensive and, most of the time is a simple task. This is a major reason why your car won’t rev past 4000 RPM in park.

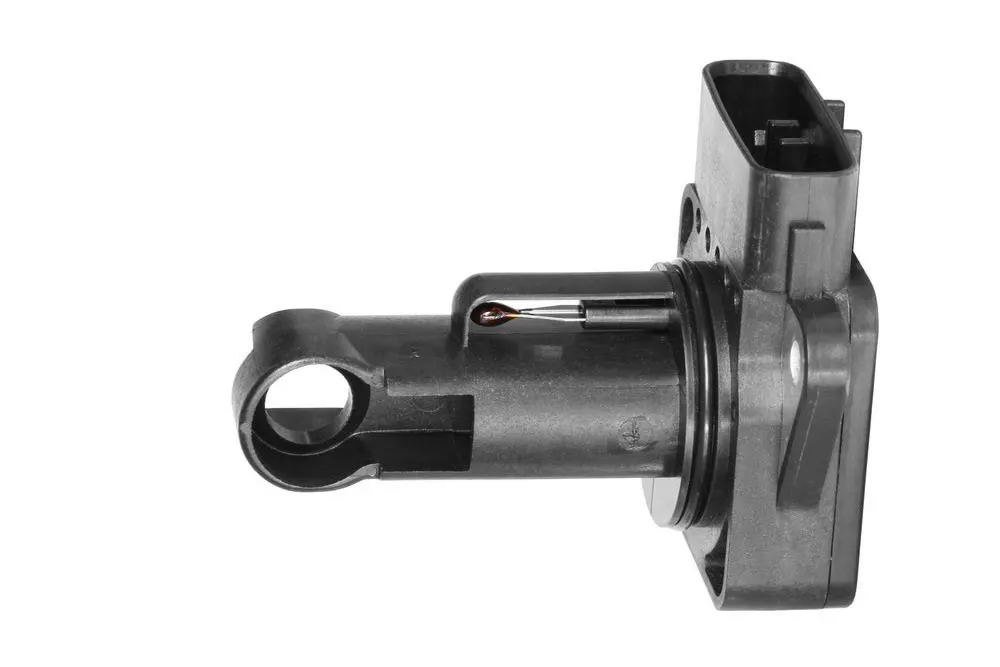

10. Defective Mass Airflow Sensor

A mass airflow sensor measures how much air enters the engine’s intake system. The ECU may then change the air-fuel mixture ratio as needed. It accomplishes this by measuring the mass airflow sensor, analyzing it in conjunction with information from other sensors, and giving the fuel injection system instructions on how to work most effectively. The engine may operate badly and exhibit symptoms including poor revving, clogged spark plugs, difficulty starting, and difficulties getting the engine to idle consistently or smoothly if this sensor is malfunctioning.

11. Clogged Fuel Filter

Every 20,000 miles or so, a gasoline filter should be replaced. If you are unsure whether the gasoline filter has been replaced on a regular basis, changing it is strongly suggested. It is simple enough for most people to accomplish and is inexpensive. This is generally an excellent place to start when troubleshooting many engine problems.

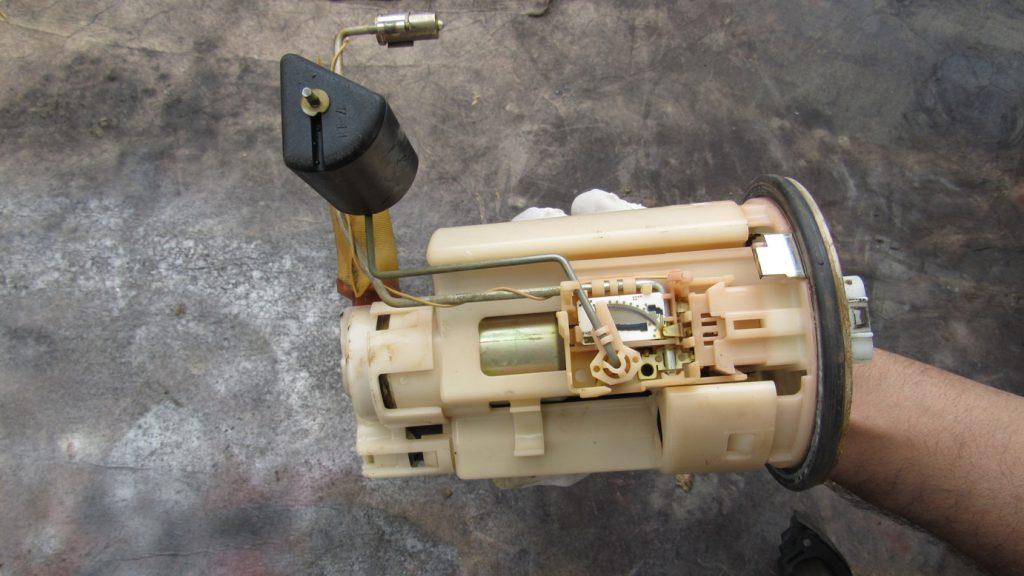

12. An Issue With The Fuel Pump

Gasoline pumps can wear out, which can result in the engine receiving insufficient fuel. Fuel deprivation frequently results in an engine not revving adequately and, on occasion, a total shutdown of the engine. Although replacing fuel pumps is often not expensive, I advise leaving the repair to a professional because it involves working closely with the gasoline tank. After the repair has been completed, careful inspections must be made to ensure no leaks are coming from the gasoline tank.

13. A Malfunctioning Accelerator Position Sensor

In certain cars, the location of the accelerator is detected by an electronic sensor. These sensors may malfunction in such a situation and provide the engine’s electronic throttle control with inaccurate information, causing the engine to run incorrectly. And in light of it, another element contributing to the issue is the engine’s computerized control. As a result, both must be investigated in order to determine which of the two is the source of the issued control. Therefore, both must be examined to determine which of the two is the source of the issue. A competent car electrician can perform the necessary tests to determine this.

14. Contaminated Fuel

Contaminants in the gasoline tank can induce a variety of symptoms, depending on the type of foreign material that has made its way into the tank. Fortunately, a gasoline filter keeps most harmful impurities out of the engine, but there are some items you never want to see in your gas tank.

Some pollutants may also cause fuel pump damage. So, if your fuel pump inexplicably fails one day, get the fuel in the tank tested. A new supply of gas at the gas station can sometimes taint the gasoline. If you believe that the fuel in your car has been tainted, leave the engine turned off until it can be investigated.

Conclusion

That is the main list of reasons why your car won’t rev past 4000 rpm in park. Only after identifying the issues responsible will you be able to solve them. This should typically be a reasonably affordable repair because most of these fixes shouldn’t be too costly, and some of them you could do yourself.

If you have doubts about the article, let us know in the comments below, and we will get back to you.

Cheers!

Read Also: https://hydraulicsuspension.com/stop-rust-on-cars/

![You are currently viewing My Car Won’t Rev Past 4000 Rpm In Park [10 Solutions]](https://hydraulicsuspension.com/wp-content/uploads/2022/12/exhuast-pipe.jpg)