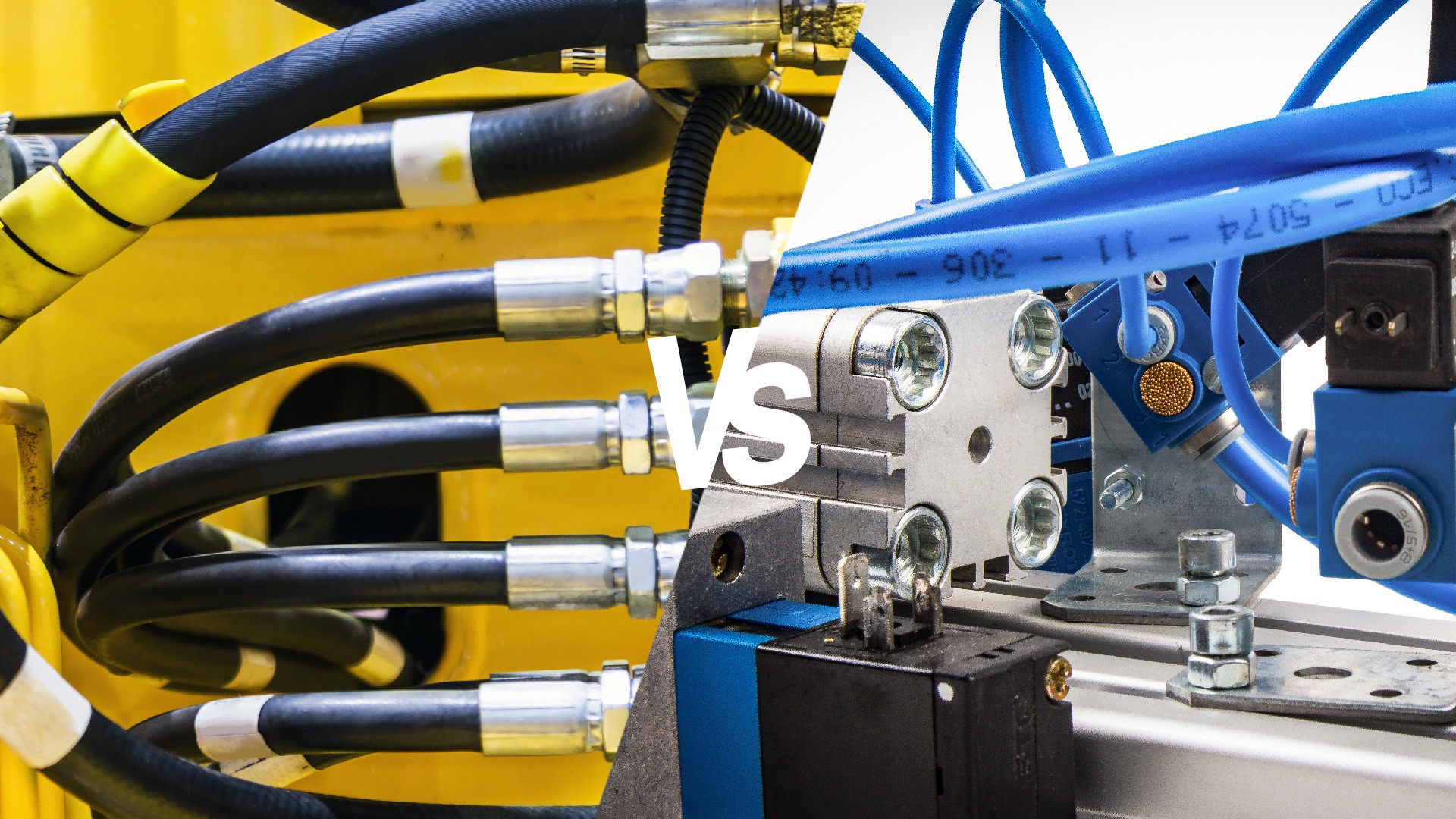

Hydraulics is a branch of science that deals with the behavior of fluids at rest as well as in motion. Pneumatics is that branch of physics or technology which uses gas or pressurized air as the main component. In this article, we will compare both Hydraulics vs pneumatics – their concept of working, advantages, and disadvantages.

Both hydraulics and pneumatics are the application of fluid power. In its fluid power applications, hydraulics is used for the generation, control, and transmission of power by the use of pressurized liquids, and in Pneumatics same is done by using air or pressurized gas.

To know the difference between Hydraulics vs pneumatics, we first got to know the basic concept of Hydraulics and pneumatics.

Let’s start with hydraulics, then pneumatics, and go with Hydraulics versus pneumatics.

Table of Contents

What Is Hydraulics?

Fluid can be defined as a substance that is capable of flowing and does not maintain its shape for a long time. Fluids can take the shape of the container depending on the surroundings and flow in a large area when the surroundings are removed.

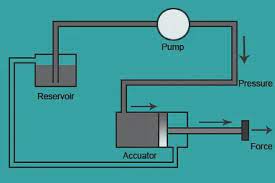

Fluid such as water is used for the conversion of hydraulic energy into mechanical energy to do some useful work. In the heating, ventilation, and air-conditioning industry (HVAC), liquid such as water is used for the transmission of heat from one area to another. The primary element of a hydraulic system is fluid, which obeys Pascal’s law to give fluid power.

Examples of Hydraulics systems:

Jaws of Life, dump truck lifts, water guns, forklifts, cranes, etc.

The above figure shows a Hydraulic system.

Advantages of Hydraulics

Below we have listed the advantages of using the Hydraulics system.

- In general, it is simple, safe, and economically easier to maintain. Hydraulic systems use fewer moving parts in comparison with other systems.

- Compared to pneumatics it is highly responsive and supplies more power than pneumatics.

- The liquid does not absorb any of the supplied energy.

- By the use of simple levers and push buttons, it can be easily controlled. The operator of a hydraulic system can easily start, stop, speed up and slow down.

Classification Of Fluid

Some of the significant types of fluid are:

- Ideal fluids

- Real fluids

- Newtonian fluids

- Non-Newtonian fluids

- Ideal plastic fluids.

- Properties of Fluids

Primary Properties Of The Fluid:

- Density or mass density or specific mass

- Specific weight

- Specific volume

- Surface tension

- Viscosity

- Surface tension

- Capillarity

- Compressibility

- Specific gravity

What Is Pneumatics?

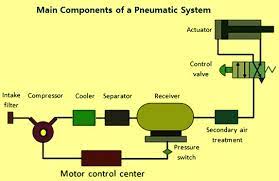

Pneumatic is that branch of physics or technology concerned with the mechanical properties of gases. Pneumatic can also be defined as a branch of fluid power in which gas is used as a fluid. There are two types of gases are used in pneumatic systems such as compressed air and Nitrogen.

Compressed air is a mixture of all gases contained in the atmosphere. The endless supply of air and the ease of condensation make compressed air the most widely used fluid for pneumatic systems.

The above figure shows a Pneumatic system.

Advantages Of Pneumatic System

Some of the major advantages of pneumatic systems are as follow:

- Availability of air.

- The compressibility of air.

- Compressed air is easy to transport in pressure vessels, containers, and pipes.

- Simple in construction and easy to handle.

- Controlling the ability to pressure, speed and force is high.

- Maintenance is low.

- Explosion-proof characteristic of the medium.

- Cost is low compared to other systems.

- Fire-proof characteristic of the medium.

- Possibilities of easy but reliable remote control.

Applications of Pneumatic Systems:

Some of the important applications of the pneumatic systems are as follows:

- Used for the packing process.

- Used for the filling process.

- In drilling, hoisting, punching, clamping, assembling, riveting.

- Opening and closing of the doors.

- Used in industrial robots.

- For power hammers and nut runners.

- Used in riveting hammers.

- Using for breaking system in automobiles, railway coaches, wagons, and printing presses.

- Used in metal forming processes.

- Used in material handling types of equipment and logic controlling operations.

Examples of Pneumatic Systems and Components:

- Air compressors and air brakes

- Air engines for pneumatically powered vehicles

- Compressed-air engine and compressed-air vehicles

- Pneumatic anti-aircraft weapon

- HVAC control systems

- A pneumatic actuator, air gun, Cylinders, motor, and tire

- Pneumatic tools: Jackhammer, nailgun

- Pressure regulator, sensor, switch

- Vacuum pump

Difference Between Hydraulics vs Pneumatics:

The below table shows the differences between Hydraulics and Pneumatics.

| Hydraulics | Pneumatics |

| 1. Hydraulics uses a liquid like water and oil. | 1. Pneumatics uses gas-like air. |

| 2. Liquids are incomprehensible, and have high specific mass and a free surface. | 2. Gases are readily compressible, have a low specific mass, and do not have a free surface. |

| 3. Hydraulic systems are used for high force and where stiffness is necessary. The motion is relatively slow but can handle high loads. |

3. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness is not required. |

| 4. The installation is complex and maintenance cost is high. | 4. Installation of this system is less complicated and maintenance cost is less. |

| 5. A tank is used to store liquid from which the system can draw liquid in case of a deficit. | 5. In this case, the system can draw air from the atmosphere and use a filter to purify it for use. |

| 6. Ex- Vehicle brakes, Hydraulic lifts, forklifts, jacks, etc. | 6. Ex- pneumatic air brakes, Nailgun, cylinders, Actuators, Air guns, etc. |

Frequently Ask Questions

-

Why do People Prefer Hydraulics to Pneumatics?

Unlike mechanical, electrical, or pneumatic fluid power systems, they can move heavier loads with more force. Produces a tremendous amount of energy

-

Does Hydraulics Have the Ability to Push and Pull?

Because the hydraulic fluid only operates on one side of the piston rod, single-acting cylinders are used when either a push or a pull force is required. The cylinder is moved in the opposite direction by another force (such as gravity, the weight of the load, or a spring).

-

Is Hydraulics Capable of Pulling?

A hydraulic cylinder (also known as a linear hydraulic motor) is a mechanical actuator that produces a linear force over a linear stroke. With just a basic hydraulic cylinder, millions of metric tonnes of pushing and pulling force can be generated.

Conclusion

If you like this article on the difference between hydraulics versus Pneumatics share it with your friends.

If you have any questions on hydraulics vs pneumatics please leave a comment below.

Cheers!